TurfMaker®

The Power of TurfMaker®

Even the base configuration TurfMaker® 325 (the smallest unit in the TurfMaker® family of machines) will mix and pump any mulch product including BFM up to 125 pounds per tank load and pump that thick slurry through at least 200 feet of hose. Typical thickness slurries can be pumped through longer hoses. Load and mix time 5 minutes.

Powerful Agitation for Fast Loading

Mix any thick “super mulch” almost instantly.

With a powerful agitation system, loading mulch is quick and easy. Fast machine loading is the key to more tank loads in any work day.

- Load and Mix Almost Instantly

- No Waiting. No Clogging.

- Easily Stir any 100% Wood Mulch

- Mix any thick “super mulch” almost instantly.

TURFMAKER® Models

TurfMaker® 550 Turf Maker® 700

TurfMaker® 800 TurfMaker® 1000

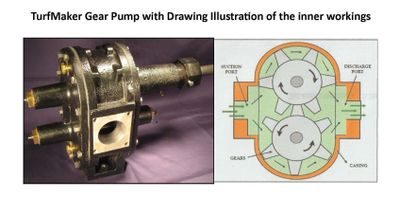

TURFMAKER® GEAR PUMPS

with steel gears are more precision internally than any other gear pump, providing better pumping power for thick slurries through long hoses.

TURFMAKER® GEAR PUMPS have incredibly hard steel surfaces throughout for much longer life.

Clear Water to Flush the Hose

Dried mulch in the hose is a major clogging problem. The system and the hose should be flushed with clear water anytime spraying is stopped for more than a few minutes. Avoiding clogs saves a lot of time.

An optional 50 gallon holding tank provides enough water for two flushes of 200 feet of hose.

The 50 gallon tank is integrated into the 1200 gallon flat top machine.

No Cross Members Inside Tank.

No Cross Members Inside Tank.

Inside a Deck and Railing Model TurfMaker®

(No mulch catch points)

No Cross Members Inside Tank.

Inside a Low Profile Model TurfMaker®

Inside a Tank - Competitor A

Gas or Diesel Engine?

TurfMaker® machines are designed in such a way that the customer has numerous engine options. Most smaller TurfMaker® machines are ordered with gasoline engines. Most larger TurfMaker® machines are ordered with diesel engines. Diesel engines cost more and typically last longer. Diesel engines are typically more fuel efficient. Note, however that gasoline engines seldom need to be replaced due to being worn out. Replacing the gas engine usually costs less than the initial upgrade cost of the original diesel engine.

Choosing Hydraulic vs Mechanical Drive Systems

A hydroseeding machine has two primary functions: A mixing paddle system in the tank to mix the slurry of water, mulch, seed, and other ingredients and a pump for pumping the mulch slurry out of the tank for application onto the ground. Powering those functions is simply a matter of turning the shaft of the mixing paddles and turning the shaft and the pump with adequate torque and speed.

Mixing in the Tank

Loading and mixing a machine quickly is important for job-site efficiency. Mechanical drive systems typically provide massive power for mixing paddles to mix the slurry almost instantly. Some hydraulic systems do not deliver adequate power for instant mixing. That lack of power is addressed with a reversing function. Reversing the paddle blade direction will help achieve adequate mixing. However, reversing the agitator to obtain adequate mixing wastes time resulting in slightly more labor costs each tank load. A hydraulic system for the agitator should be designed to provide enough power for instant mixing and include reversing.

Pumping from the Tank

The most important pumping function for hose applications is the ability to pump thick slurries through long hoses. The most important pumping function for tower applications is to shoot any slurry, thick or thin sufficient distances. Whether or not the pump is driven with a mechanical system or a hydraulic system is of no importance if the pump is turned with adequate power and speed.

Points of Comparison

Any system, including hydraulics, is subject to good or poor design. Any system will wear out. Any system has it’s strong points and weak points. Below are a few of these points.

- Hydraulic systems eliminate the need for clutches, belts, or chains. Any of these components can be a failure point. However, hydraulic systems have hoses and other components that fail. Hydraulic failures will most likely require special order parts resulting in more time down time to make repairs.

- Hydraulic systems can be designed to easily reverse the direction of the agitator or pump.

Reversing the agitator is valuable if the agitation system is weak. Reversing the agitator is also useful to deal with a common operator error of getting too much water in the tank before all the mulch is loaded.

This occurs when water is allowed to fill the tank too quickly. Reversing the agitator will take the mulch floating on top down into the mixing paddles and into solution.

Reversing a gear pump is very useful. If a clog occurs somewhere in the system, reversing a gear pump will most likely clear the clog. A centrifugal pump does not work in reverse.

- Hydraulic systems typically require 15%-20% more horsepower to deliver the same amount of power to the agitator and pump. TurfMaker® mechanical machines with lower horsepower engines are less expensive than hydraulic machines and usually outperform competitors hydraulic powered machines

SUMMARY – Hydraulic Power Systems versus Mechanical Power Mechanisms:

- For the actual performance of the machine, it simply doesn’t matter.

- Reversing systems with hydraulics provide better recovery from operator error.

- Reversing systems with hydraulics provide conveniences and user friendliness.

- Praise or criticism of one system versus the other is usually related to good or poor design.

- Annual maintenance costs are not significantly different.

- Hydraulic systems require 15%-20% more horsepower.

- Hydraulic systems costs more, plus the costs of a larger engine.

Collapsible Hose or Hard Hose - The User's Choice

Collapsible Hose

Operators typically prefer lighter weight collapsible hose. This is particularly significant when more than 100 feet of hose is needed. It is not uncommon for a jobsite to require more than 150 feet of hose.

Multiple sections of hose can be coupled together to reach the farthest point on a job site and lightweight hose is usually preferable.

A clear water hose flush system on a machine can pump clear water through the hose at any time.

Whenever hose is pulled out or reeled in, an empty hose is lightweight and easy to handle. Flushing with clear water also eliminates any possibility of hose clogging.

Hard Hose

Hard hose (non-collapsible) allows a machine to be equipped with a live hose reel*. An amount of hose can be unwound and the pumping of mulch can begin with some of the hose still wrapped on the reel.

This is certainly convenient. The mulch slurry flows through the piping of the reel and into the hose.

Another advantage of hard hose is that it is more durable than collapsible hose and less likely to kink.

On the negative side, hard hoses are heavy. When full of mulch, a 1½” hard hose will weigh about 175 pounds per 100 feet. Hard hose is awkward to handle and transport without a powered hose reel. Further, a live hose reel* requires significantly more pumping power to provide adequate pressure at the end of the hose. Perhaps the most compelling reason not to use a live hose reel* is that clogs can easily occur in the pipes and hose of a live hose reel. Such a clog can be a major problem.

One Final Note

A live hose reel* with hard hose (non-collapsible) is much more tolerable if the machine is equipped with a clear water system AND a reversible gear pump. Both features will provide for the reel and hose being cleared of mulch at the end of every work session.

*A live hose reel has the hose connected to the plumbing of the reel so that the material being pumped flows through the reel and through the hose wrapped on the reel. Any amount of hose can be removed from the reel or re-wound back onto the reel while making an application. Historically this type of system has caused clogging. However, the use of tackifiers (providing lubricity) has reduced this nuisance significantly. Also, reels used by TurfMaker® are less clog prone than typical reels.

Shop New Hydroseeders For Sale

💸 Easy Financing with No Impact to Personal Credit

⚠️ Don’t let cash flow slow your business down!

We’ve partnered with Geneva Capital to offer a Soft Pull Financing Option — meaning:

✅ No hard credit check required to apply.

✅ See your financing terms without impacting your personal credit score.

✅ Fast approvals – get your equipment now, pay later.

🚀 Apply Now: hydroseedsupply.gogc.com

📅 Current Promo: Just $0 Down and $0/month for your first 3 months with promo code 2025Q4 (on approved credit)